Flexible viscoelastic tape

Manual of flexible viscoelastic anticorrosive tape

1. Product overview

Our flexible viscoelastic tape not only has all the material properties of STOPAQ viscoelastic tape, but also has flexibility and better resilience, which can be stretched 3 times the original length. The tape can be deformed into any shape to adapt to the integrity of various special-shaped pipe fittings, variable-diameter pipelines and mending sleeves without gap filling and covering. It is necessary to use our company's viscoelastic body paste. Due to the use of two different substrate technologies, tapes are divided into low temperature and high temperature application types. The low-temperature viscoelastic tape uses a resilient film to make the substrate, which is suitable for individual applications at low temperatures; the high-temperature viscoelastic tape uses a superplastic film to make the substrate, which is suitable for use with an outer protective tape at high temperatures.

|

|

|

2. Product features

2.1 No need for sandblasting, lower surface treatment requirements, ST3 level.

2.2 Wide operating temperature range, -30-+80℃.

2.3 No need to paint primer, it can be directly bonded to 3PE, FBE, liquid epoxy coating, asphalt, PP and other coatings.

2.4 The pure olefin polymer has the same chemical stability as polyethylene plastic, excellent corrosion resistance and reliability.

2.5 Flexible extension up to 3 times the length of its own, used for the integrity of special-shaped pipe fittings, variable diameter pipelines, internal anti-corrosion layer of mending, and external anti-corrosion of mending sleeves, no gaps and no wrinkles.

2.6 The construction is simple, convenient and fast, the construction quality is easy to control, and it is less affected by the technical level of the personnel and the environment.

2.7 Minor mechanical damage can repair itself.

2.8 Does not age, the service life is more than 40 years.

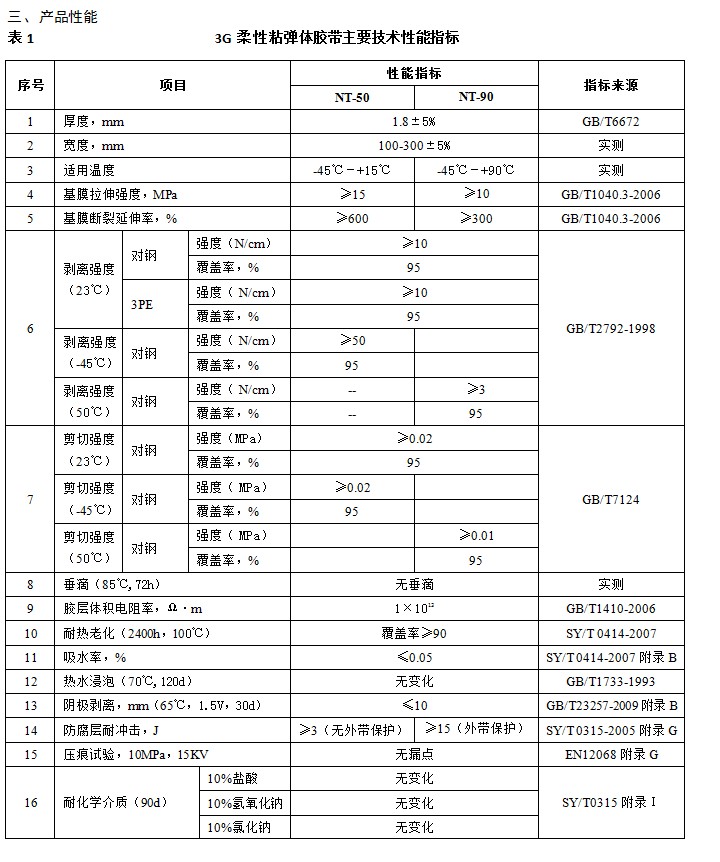

Product performance

The form of product provision

Tape is provided by roll, each roll is 10m in length, and the width can provide four specifications of 50mm, 100mm, 150mm, 300mm. Release material: 5sPET release film. The inner packaging is vacuum packaging and the outer carton packaging.

|

|

|

5、Product use

Pipeline anticorrosion coating overhaul, partial repair, elbow anticorrosion coating production, pipeline repairing, and new pipeline repairing internal anticorrosion coating production.

6、Use reference

6.1 Construction environment: ≥-30℃ can be constructed. Do not construct in rainy and snowy weather, RH≥85% or water on the pipeline surface.

6.2 Surface treatment: Asphalt or epoxy coal tar enamel needs to be cleaned. The fusion-bonded epoxy powder coating and 3-layer PE anti-corrosion layer can be wiped and dust-free by hand. The surface derusting grade is ST2, and the surface is free of floats and grease.

6.3 The use of adhesive tape: manual winding with high tension, the release film on the adhesive tape shall not be peeled from the adhesive tape when it is not in use.

6.4 Quality inspection: Re-inspection and sample preparation must be tested 1 day later, and pipeline anti-corrosion layer quality inspection must be tested 1 day after winding. The tensile speed for testing peel strength should be ≥200mm/min.

6.5 Storage and transportation: Store indoors at -10-35℃, away from fire, no exposure to the sun, water, rain, or freezing. Storage period: 18 months.

For specific construction technology, please refer to the construction technical plan manual provided by our company.

|

|

|